Water is used in the production of pig iron and crude steel for cooling and for the generation of steam and is therefore one of the most important consumables and auxiliary materials. Conservation of water resources, which takes local circumstances into particular consideration, is achieved by methods that include closed-circuit systems and multiple use of process water.

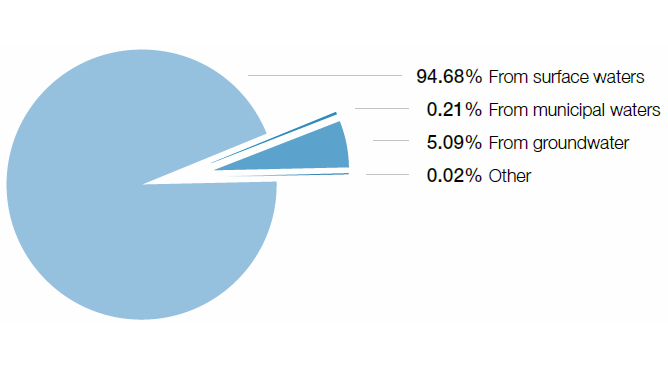

The total withdrawal quantity by the production companies of the voestalpine Group, which were included in the collection of environmental data, was 678.8 million m3 in 2015. The majority of the water is from surface water, which is used for cooling purpose.

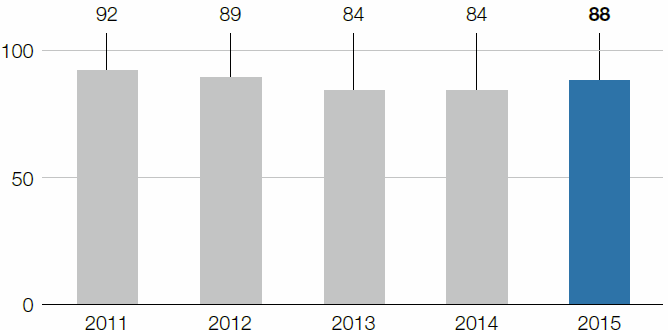

The total specific volume of water required is 88 m3 per ton of crude steel, and this figure has remained largely constant during recent years.

The wastewater discharge represents the water volume that is routed into discharge systems or into the public sewer system after being purified with state-of-the-art methods. The wastewater discharge by the production companies of the voestalpine Group was kept at about the same level in recent years.

Specific total water requirement

m3/t of crude steel

Water withdrawal according to source 2015

Villares Metals, Brazil

By building two reservoirs, which have a total capacity of 11 million liters of recyclable water, water consumption from local wells was reduced by around 30%. The project was awarded first place in the Group-internal CIP (continuous improvement program) Awards 2014 in the “Environmental Protection” category.

Böhler Profil GmbH: Hydropower plant on the Ybbs River, Austria

- Renovation of the power plant with an increase in performance of around 15% from the original 2.3 GW

- Electricity self-sufficiency of around 90%

- Construction of fish ladders

Furthermore, fish ladders were built or improved at the Austrian locations of Donawitz, Zeltweg, and Bruck.

Ensuring water quality at the Linz, Austria, site

All of the cooling water from the production facilities at the voestalpine Linz site is routed into the Danube or Traun Rivers. After being purified, operational wastewater is either routed into the Danube or into the Asten regional sewage treatment plant, where it is again treated biologically depending on its ingredients.

Wastewater discharge is continuously monitored. The cooling water is constantly tracked and monitored as far as water volume and discharge temperature are concerned. Operational wastewater is monitored and recorded with regard to water volume, temperature, and pH. Furthermore, samples are regularly taken and analyzed in accordance with defined organic and anorganic parameters.

Share page