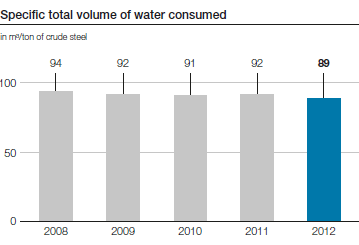

Conservation of water resources, which takes local circumstances into particular consideration, is a core principle for voestalpine. Closed circuit systems and modern production facilities and processes enable multiple use of process water and a decreased need for industrial water, respectively. In the 2012 calendar year, the production companies of the voestalpine Group consumed and discharged around 89 m3 of water per ton of crude steel. The figures are within the naturally occurring fluctuation range of the production process.

The total volume of water consumed represents the water volume that is routed into discharge systems or into the public sewer system after state-of-the-art treatment.

CO2-neutral hydropower combined with economic profitability and energy efficiency

The site in Zeltweg, Austria (voestalpine turnout systems) participated in the expansion of a small hydropower plant on the Pöls River. The objective was to supply the site with electricity from clean, CO2-neutral hydropower as self-sufficiently as possible. Economic profitability and attention to aspects related to water law and environmental issues during construction and operation of the power plant were major planning factors. A significant part of the electricity production is being utilized for a new induction heating system for forging of rails, which replaced the previous natural gas-operated furnace; this enables a reduction of 340 tons of CO2 emissions annually. The facility also ensures voestalpine’s technological market leadership, thus helping to secure the approximately 50 jobs at this site. An expert opinion provided by the University of Technology in Graz confirmed that the construction of this power plant created added value for Austria of more than EUR 10 million, thus producing a high benefit for both the regional and the national economy.