Crude steel

voestalpine analyzes and manages sustainability along the supply chain through existing and new processes, especially by means of risk management, the purchasing terms and conditions, and the recently developed project Sustainable Supply Chain Management (SSCM):

Risk management

A general Group-wide policy, which was approved by the CFO of voestalpine AG, sets forth how the Group’s operational risk management is set up systematically and performed on a regular basis.

The risk categories range from strategic risks and market and financial risks to personnel, environmental, IT, and compliance risks.

The risk management process is performed by the Group companies at least four times per year; this means that the risks are examined, evaluated, monitored, and, if necessary, updated. This process also provides the basis for discussion for any improvements within the risk management system. As the Group is very heterogeneous, there is no centralized supplier evaluation. Instead this evaluation is up to the individual companies. Evaluation results are, however, coordinated among the companies.

To learn more about voestalpine risk management please visit: Report on company risk exposure

Purchasing terms and conditions

voestalpine’s purchasing terms and conditions apply to all suppliers. The Code of Conduct for voestalpine Business Partners and the certification requirements have been an integral part of these terms and conditions for some years. The Code of Conduct was revised and contains explicit regulations that refer to sustainability issues, for example, human rights, environmental protection, working conditions, and work safety.

SSCM project

In order to improve transparency in voestalpine’s own supply chains, the SSCM project was introduced in the spring of 2016. In a multiple-phase project, voestalpine experts from the Corporate Responsibility, Purchasing and Raw Materials Purchasing, and Quality Assurance units, together with the assistance of an international expert in the area of supply chain analysis, assess suppliers and countries of origin with regard to pre-defined risks—from the extraction of raw materials to the point when products leave the voestalpine plants. These risks apply primarily to environmental issues, social issues such as human rights and working conditions, and compliance and corporate governance.

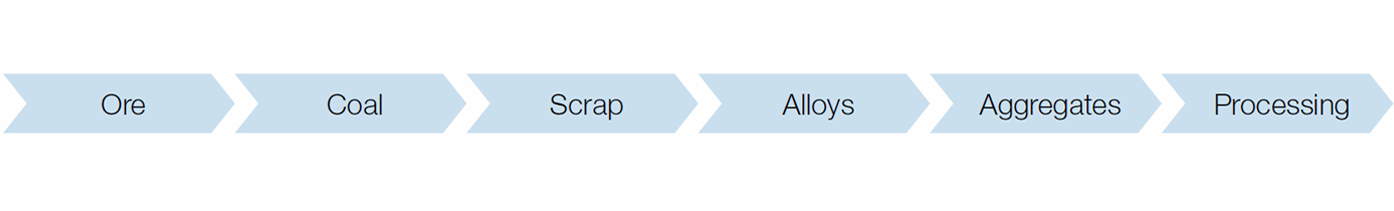

Considering the large number of suppliers (multiple tens of thousands) and the geographic diversity (suppliers on all of the five continents), the essential first step is to define the most important raw materials and other materials in order to then set up a systematic process to create sustainable supply chain management system using a number of supply chains as examples. A typical supply chain from the steel production sector was developed as an initial step.

Development of a supply chain from the steel production sector to be used as an example

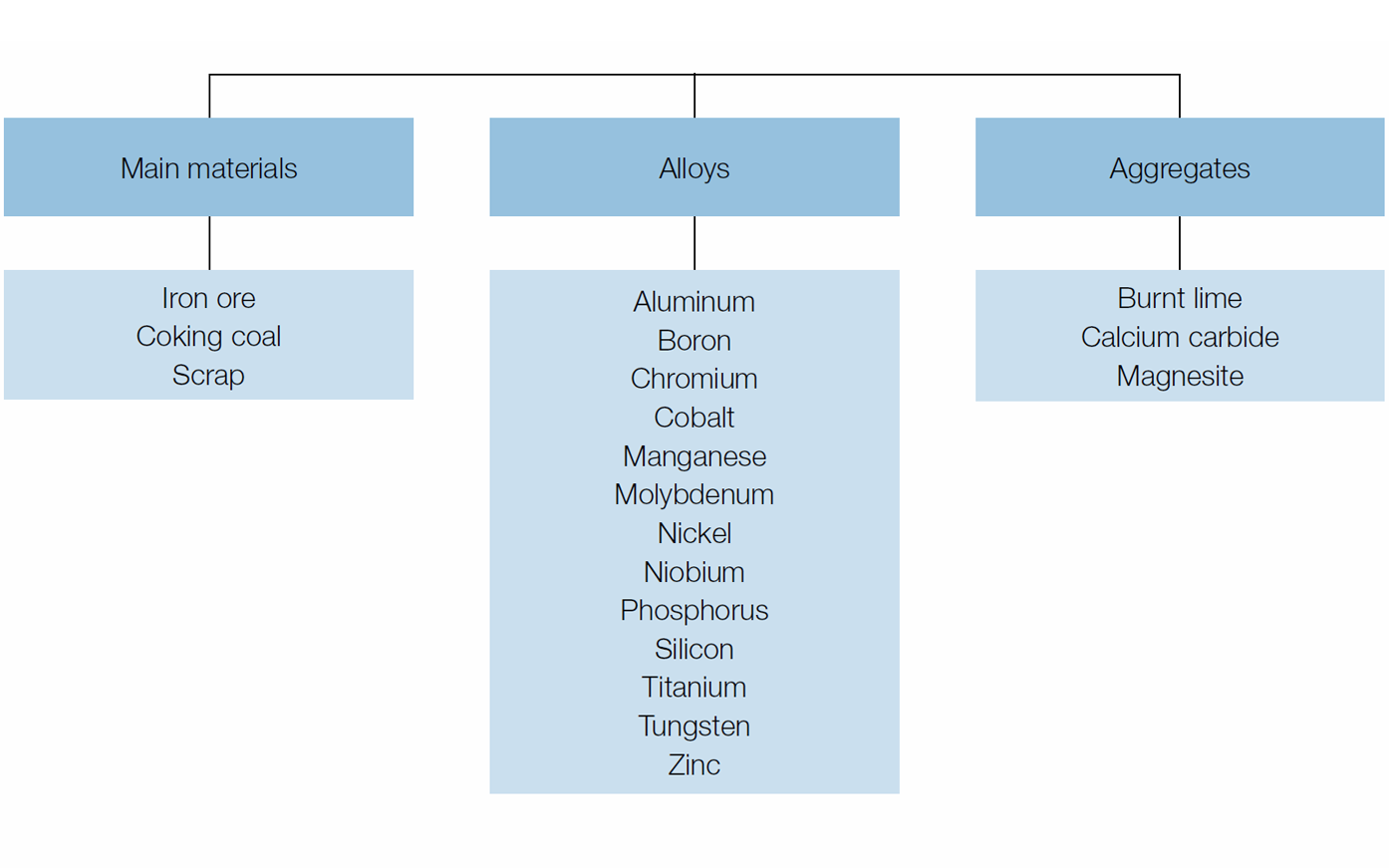

The following raw materials and other materials were defined as significant for this exemplary supply chain and were therefore examined more closely:

Subsequently, the countries of origin and suppliers of these materials and raw materials were determined. All material/country/supplier combinations were analyzed for the previously mentioned risks. In addition to this research, interviews are being conducted with selected internal and external stakeholders with regard to these risks.

After completing this process, the results will be analyzed, and further measures will be developed and implemented. The SSCM will be successively applied to all of the major value chains in the voestalpine Group.

Share page