Energy efficiency in the steel industry is a constant challenge—for cost reasons alone. Energy intensity is directly associated with CO2 intensity (see chapters “Air emissions” and “Energy and climate policy”). In the classic integrated metallurgical facilities, an increase in efficiency can be achieved, for example, by optimizing process gases generated during production by increasing thermal recycling of these gases and utilizing waste heat potential.

Against the backdrop of political decisions (keyword energy paradigm shift), this subject gains additional significance in the long term. As the steel production locations of the voestalpine Group are currently to a great extent self-sufficient with regard to generation of electricity (integrated energy cycles based on fossil coal/coke utilize occurring process gases; conversion into electricity takes place in separate power plants, and energy is routed back into the production process), the decarbonization of products is connected with the challenge of how fossil energy can be replaced in the future by electricity from renewable sources from an external network.

Environmental action by Böhler Edelstahl GmbH & Co KG, Kapfenberg, Austria:

In 2005, the first waste heat recovery facilities were installed at the Kapfenberg location. Today, five installations with a capacity of 13 GWh/year are in use, which not only cover in-house consumption but also provide heat for the city of Kapfenberg. Similar models, which provide excess electricity from production to external grids, also exist at other major locations, for example, Linz and Leoben-Donawitz.

Total energy consumption of the voestalpine Group in 2015 was 37.88 TWh; the largest consumer is the Linz location.

Breaking down the energy sources, the largest ones are, of course, coal (54.7%) and coke (20.3%), followed by natural gas (16.7%). At 5.9% of total energy consumption, the purchase of additional electricity is a comparatively minor factor.

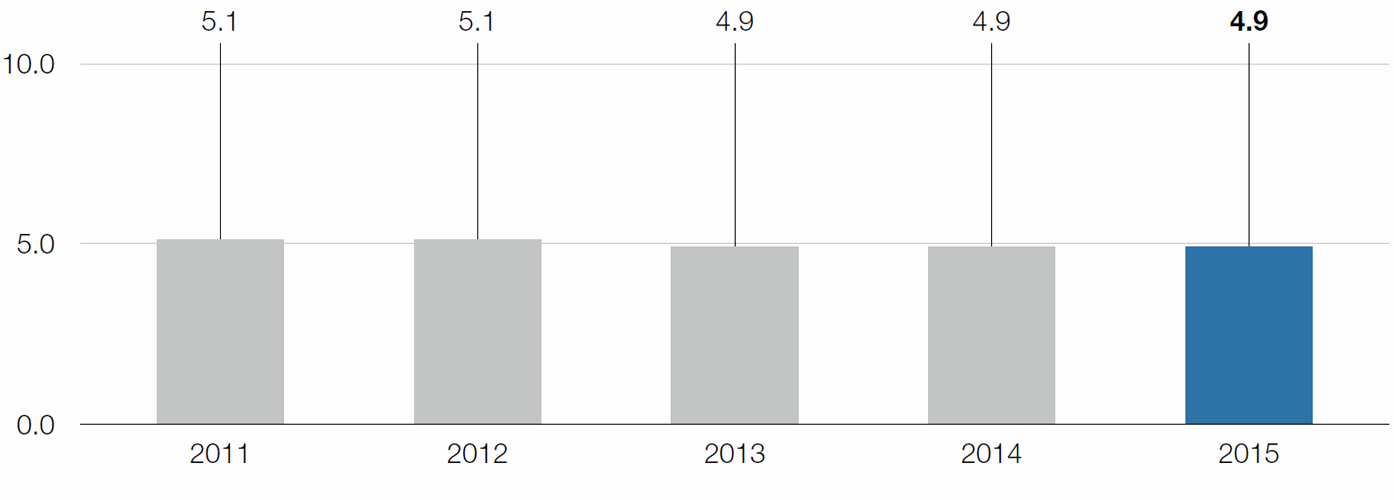

Specific energy consumption is 4.9 MWh per ton of crude steel, thus remaining practically unchanged during the past five years.

Specific total energy consumption

MWh/t of crude steel

Share page