The political framework

The political guideposts described in the Corporate Responsibility Report 2020 are still being debated. While the Paris Climate Agreement that was adopted at the UN’s Climate Change Conference in 2015 still is very far from being a global framework, the European Union and individual member states such as Austria have fleshed out their political climate goals in the meantime and have revised them upward. The European Green Deal, which was initiated at the end of 2019, significantly increases the emissions reduction targets that apply up to 2030. The European Commission, Council, and Parliament agreed to a tightening of the targets from previously 40% to a minimum of 55% (in each case relative to 1990). On July 14, 2021, the EU Commission presented a comprehensive package of legislative proposals titled “Fit for 55” that aims to align the directives and regulations regarding the future EU Emissions Trading System (EU ETS) as well as topics such as CO2 carbon border adjustments (CBAs), energy efficiency, expansion of renewables, state aid, or energy taxes with the new target. The Commission’s proposals are now being negotiated with both the EU Parliament and the member states via the trilogue procedure. It is to be expected that the target for reducing emissions by 2030, which applies to sectors such as the steel industry that are subject to the EU ETS, will be raised from 43% to 61% relative to 2005. It is likely, too, that the planned cancellation of allowances in conjunction with both the planned expiration of the no-cost allocations and the simultaneous introduction of a carbon border adjustment mechanism (CBAM) will result in a significant cost increase. The resulting consequences for voestalpine were evaluated in detail at the time the present CR Report was prepared. Austria’s federal government, for its part, has proposed achieving climate neutrality “by no later than 2040” and thus a decade earlier than the EU. The resolutions that it discussed and/or adopted during the reporting period concern the Austrian Expansion of Renewables Act (Erneuerbaren-Ausbaugesetz, EAG) and a new climate action law. Moreover, the government agreed in the fall of 2020 to amend the Austrian Emissions Allowances Act (Emissionszertifikategesetz, EZG) so that national EU ETS auction revenue can be allotted to the given companies for specific decarbonization measures. For one, budgetary allocation of national funding and European co-funding is the prerequisite for achieving the ambitious climate goals. For another, green energy must be available in adequate quantities and at reasonable costs so that energy-intensive industries can lower their emissions in the required scope while remaining competitive. Both at the level of the EU and nationally, voestalpine thus is in constant talks—directly and via industry associations—with political decision makers, the science community, environmental organizations, and industrial partners in research and development. voestalpine’s registration in the applicable national and international lobbying lists (Austria: LIVR-00925, EU: 189510925414-06) ensures additional transparency.

EU emissions trading

The European Union’s Emissions Trading System encompasses about 11,000 energy-intensive plants (primarily electricity generation facilities and manufacturing industries) and provides the current framework for decarbonization by 2030. As a result, it also is voestalpine’s central parameter for planning concrete implementation measures. Sectors subject to the EU ETS must buy one allowance for every ton of carbon dioxide they emit. The allowances must be purchased through auctions, and the proceeds from the sale of the allowances must flow into the respective national budgets. While the funds are supposed to be earmarked for projects that contribute to the energy and climate transition, individual EU member states have embraced different approaches to this flexible provision of the EU ETS.

In order to lower the risk of production off-shoring owing to different countries’ different climate action standards (also known as “carbon leakage”), a certain number of no-cost allowances are allocated to the affected industries.

The EU Commission classifies the steel industry as the sector having the highest carbon leakage risk. Theoretically, therefore, absolutely all of the allowances to be allocated to those 10% of facilities that are ranked “best” relative to EU benchmarks are supposed to be free of charge. In actual practice, however, the percentage of allocated no-cost allowances is a lot lower. Just as in previous years on average, in the business year 2020/21 the voestalpine Group’s need to buy additional allowances (difference between its overall need for allowances less allocated no-cost allowances) equated to about one third of its total CO2 emissions of some 12 million tons.

The total number of emissions trading allowances available to the EU ETS is to be lowered in stages by the year 2030; in addition to the linear reduction, at any time this may also involve other changes to the trading system. The ensuing uncertainty complicates planning and forecasting, not least with respect to the development of allowance pricing.

Decarbonization: voestalpine’s approach to the transformation

As already addressed in earlier CR Reports, voestalpine is pursuing a comprehensive plan for decarbonizing its steel production. The first milestone is planned for 2030. Specifically, this entails reducing process-related CO2 emissions by about 30%, which corresponds to approximately three to four million tons annually. (To compare: In 2019, voestalpine’s direct CO2 emissions in Austria amounted to some 12 million tons.)

By the year 2050, the company wants to achieve carbon-neutral production by completely replacing coal as the reducing agent with electricity from renewable sources and green hydrogen. The decarbonization process is not linear. Instead, it proceeds in stages that involve the simultaneous optimization of existent technological processes.

In the short term, for example, it should be possible to lower direct carbon dioxide emissions by up to 10% in the production of crude steel for flat products, especially by optimizing both input materials and reducing agents. As any CO2 optimized process typically incurs additional costs, however, voestalpine is also developing viable business models for that purpose.

greentec steel: The innovative hybrid approach

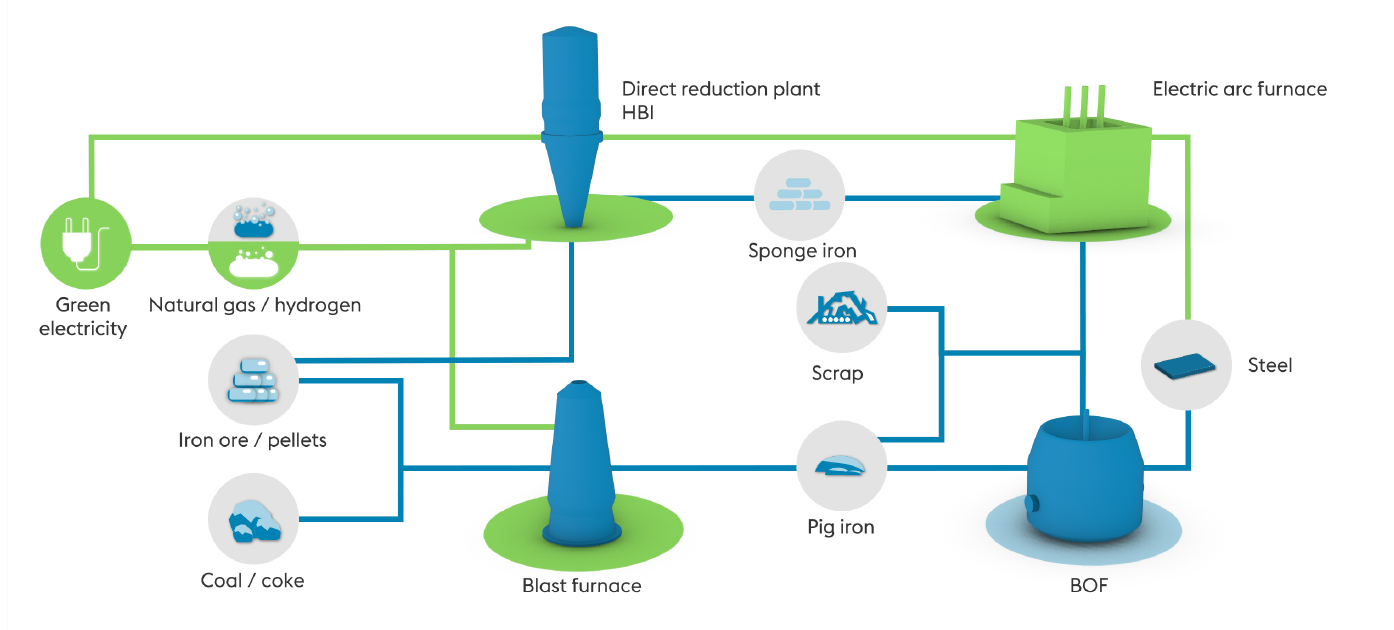

The greentec steel project serves to convert the coal-based blast furnace steel production route in stages to an electric steel route based on green electricity by 2030—with product quality remaining high.

This transformation is intended not only to enable significant cuts in carbon emissions but also and in particular to pave the way for hydrogen-based decarbonization by 2050.

Hybrid steel plant by 2030

Using HBI as a high quality pre-material

Just replacing one blast furnace each in Linz and Donawitz (Austria) with electric furnaces in a first transformative step will require investments of about EUR one billion. The company cannot pay for these expenditures and the increases in operating costs resulting from green electricity all by itself. Support programs such as the EU ETS Innovation Fund can help to offset the additional expenses. Hence voestalpine submitted an application for its greentec steel project to the fund, which issued a positive assessment in March 2020 as part of the application process’s first phase. The funding program, “Important Projects of Common European Interest” (IPCEI), is an additional source of funds that was established to strengthen European value chains.

Over and above issues of technological feasibility, the availability of renewable energies in sufficient quantities and at competitive prices and/or their distribution via efficient electrical grids are fundamental prerequisites for decarbonization to succeed. This applies both to the implementation of a hybrid technology using electric arc furnaces and to the long-term technological transformation based on green hydrogen. The Austrian Power Grid (APG) is conducting an environmental compatibility assessment regarding the expansion (from 110 kV to 220 kV transmission lines) of the electrical infrastructure in Upper Austria (a core region) that is required by 2030 for electrification purposes.

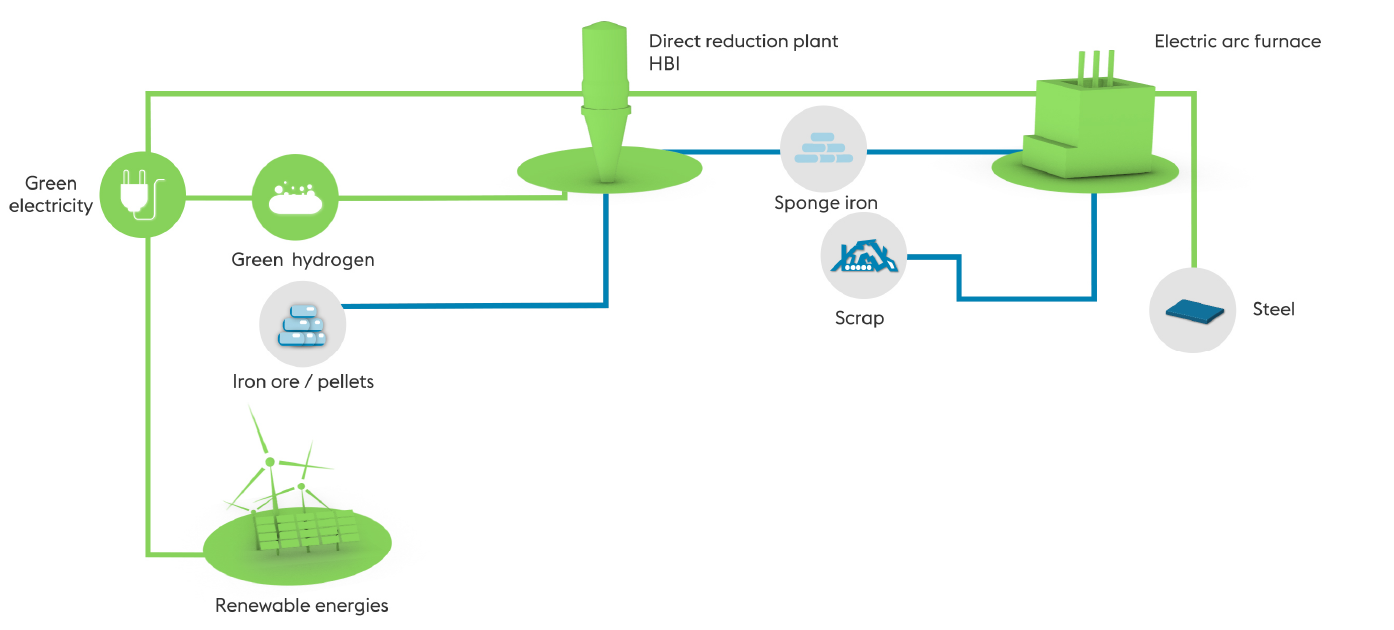

Vision for a green hydrogen future

Hydrogen-based steel production

Carbon-neutral production by 2050

The complete transformation from carbon to hydrogen as a reducing agent in both Linz and Donawitz as well as at the DRI plant in Texas, USA, requires an amount of hydrogen that equates to roughly 500 times the capacity of the H2FUTURE pilot plant.

This shows that two factors will be key to the feasibility of decarbonization: research and development of a scalable process technology for major industries, for one, and the continuous and reliably stable availability of green energy at competitive prices, for another. The implementation of both generation and distribution capacities will be realistic only at the pan-European level.

Research and development highlights

voestalpine undertakes intensive collaborative work with partners in industry and science on research and demonstration projects to technologically prepare the envisioned hydrogen-based production of steel. In addition to H2FUTURE—the world’s largest proton exchange membrane (PEM) electrolyzer facility for generating and utilizing green hydrogen at the company’s plant in Linz—two other fundamental projects are being carried out at the company’s facility in Donawitz. For one, research is being conducted as part of the Sustainable Steelmaking (SuSteel) project on technology for producing steel directly from iron ore. This involves the production of steel using a smelting reduction of ores based on hydrogen plasma that omits the pig iron stage. For another, the hydrogen-based fine ore reduction (Hyfor) project involves developing a process for reducing ultrafine iron ores in a fluidized bed using hydrogen. A pilot plant is currently being built for this purpose. Assuming that the requisite infrastructure is both economically feasible and available, the plan is to bring about the complete shift to green hydrogen by 2050.

Moreover, voestalpine has developed a scalable process for enabling carbon-neutral steel production without the use of fossil carbon and has obtained a patent for it from the European Patent Office. This patent applies in all of Europe’s major steelmaking countries and enables the production of sponge iron (DRI or HBI) in the direct reduction process using green hydrogen and biogas.