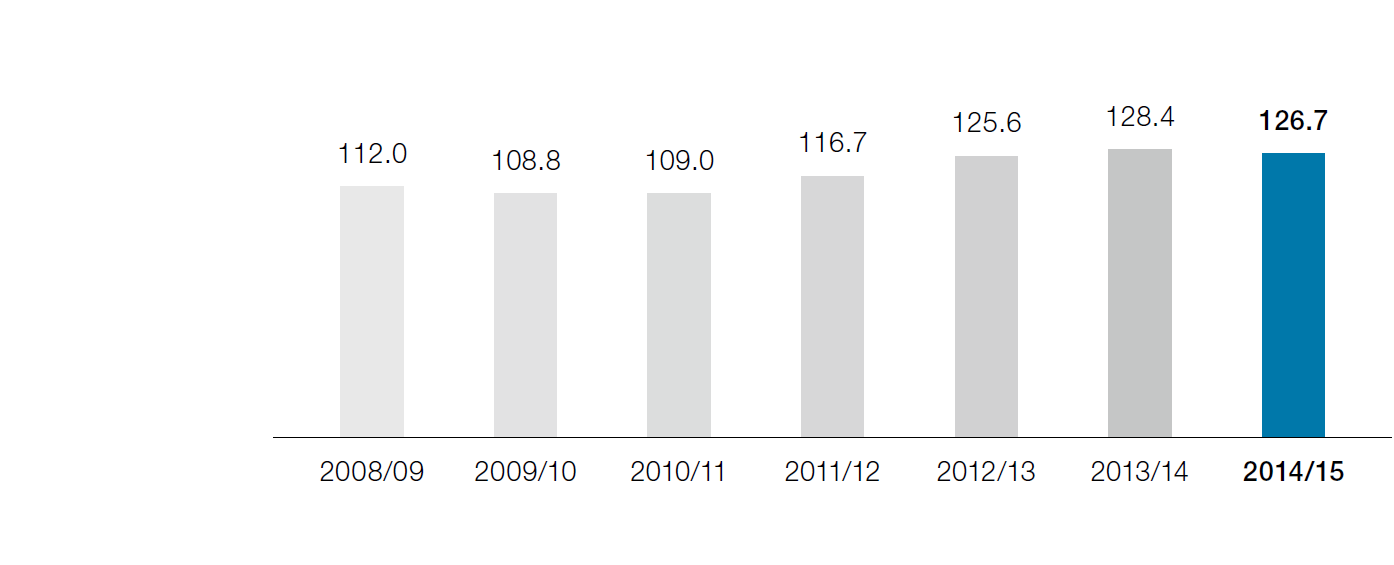

In the business year 2014/15, research and development expenditure by the voestalpine Group was slightly reduced by 1.3% to EUR 126.7 million compared to the previous business year (EUR 128.4 million). In a year-over-year comparison, the research ratio (proportion of R&D expenditures in relation to revenue) decreased from 1.2% to 1.1%; the R&D coefficient (funds measured in terms of value creation) went down from 2.9% to 2.8%.

Research expenses for the voestalpine Group

In millions of euros

R&D gross expenses (without R&D installation investments)

These investments in the company’s future found wide recognition among voestalpine’s international peers. They are also being rewarded. For example, voestalpine was recently awarded the Austrian National Prize for Innovation 2015 by the Federal Minister for Science, Research and Economy for the new ultra high-tensile strength steel phs-ultraform. As a result of pressure on the automobile industry to drive lightweight construction forward and the desire for increased safety, use of press-hardened components in body-in-white production has risen enormously. These parts are used in the automobile industry for safety-relevant structural components and body components used for the passenger compartment as well as in areas that are susceptible to corrosion. With the development of the “direct process” for the forming process of press-hardened steel, simple components can now be manufactured very cost-effectively. The first such facility is currently being built.

In the long term, research and development at voestalpine is oriented toward generating innovative complete solutions with the goal of achieving both maximum benefit for the customer and reduced life cycle costs.

Within the scope of the Group project “KW50+,” know-how and process development for the production of components made of new materials for low-carbon steam power plants are being advanced across multiple divisions. In this context, a new highly temperature-resistant casting material has already been successfully introduced on the market, and the welding process qualification has also already been completed. The pilot production of components made of nickel-based alloys as well as development of processes for seam welding of dissimilar metals (nickel-based alloys with steel) have been successful.

In another Group project, the value chain from tool steel to tool user was critically examined. As the Group has all of the expertise necessary for such an analysis, such as production of tool steel, heat treatment, and coating, but also has tool manufacturers and tool users in the Group, new fundamental insights can be gained that result in significantly improved productivity. The topic “Tools/dies and tool/die materials,” in other words, tools and forming tools and the materials necessary for the process, was the title of this year’s eighth annual R&D Synergy Platform, which was organized by the Group in Kapfenberg, Styria. Lectures by experts from all the divisions provided an excellent overview of the Group’s position; lectures by external speakers brought additional input and fresh aspects.

In accordance with its decentralized R&D strategies, the Special Steel Division is conducting research at production sites in Austria, Germany, Sweden, and Brazil; the focal points are further development of high-performance tool steel and the development of special materials for the oil and natural gas industries, energy production, and the aviation industry. In addition to pure materials development, the current R&D portfolio in this sector also comprises the development of processing technologies and new products for the aviation industry as well as new projects concerning the hard coating of tools, including the coating facilities needed for these processes.

Another research project in the Steel Division was put into actual practice under the name “Möllerradar” (batch radar) and the measuring equipment was installed on a blast furnace at the Linz site. It maps the topography of and the temperature distribution on the batch surface during production in real time; this enables optimized process management, which in turn results in reduced consumption of reducing agents in the blast furnace process.

DOBAIN®, the tear-resistant bainitic brand of rail steel, a trend-setting product by the Metal Engineering Division, continues to be tested throughout Europe on various test tracks. Due to its outstanding cold resistance, it offers additional safety when used at extremely low temperatures. The newly developed type of rail steel for the tram segment with superior welding and wear properties has found acceptance on the market and is proving to be highly effective.

voestalpine is participating in numerous research projects and is cooperating with various competence centers. Under “HORIZON 2020,” the new EU Framework Program for Innovation and Research, voestalpine is participating in the “SPIRE” and S2R programs. “SPIRE” stands for “Sustainable Process Industry through Resource and Energy Efficiency” and is an initiative of energy-intensive industries whose common goal is to develop new, cross-sector energy and resource-efficient solutions. S2R (Shift to Rail) has the objective of increasingly shifting transport volume to railroads; both voestalpine Schienen GmbH and the Turnout Systems business segment are participating in this project as part of VVAC (Virtual Vehicle Austria Consortium) with new and improved products.

In the Austrian COMET research program, for example, voestalpine is involved with ten different competence centers and projects on various priority issues. The collaboration with competence centers significantly supports voestalpine research and development, as it is possible to implement research results in practical applications on an ongoing basis. Within the scope of the third tender of the Austrian Research Funding Program, voestalpine is a key participant at two competence centers, CEST (Center of Competence in Electrochemical Surface Technology) and K1-MET (Competence Center for Excellent Technologies in Advanced Metallurgical and Environmental Process Development). The term for the projects is eight years in both cases (with a “stop-or-go” evaluation in the fourth year).

An endowed professorship to be set up in Austria on the topic of “Steel, a high-performance material,” which was suggested by voestalpine, was put out to tender by the Austrian Federal Ministry for Transport, Innovation and Technology as a measure to support areas of knowledge that are important for Austria as a location for innovation. The winning bid was made by the Leoben University of Mining and Metallurgy with its idea of a professorship for “Steel design.”

Share page