The currently available technology used in the production of high-quality steel products using the blast furnace route has been highly optimized; the same applies to the facilities and processes of voestalpine.

Improvements have already been made in the past so that the required carbon input and the resulting CO2 emissions are now close to the theoretic minimum.

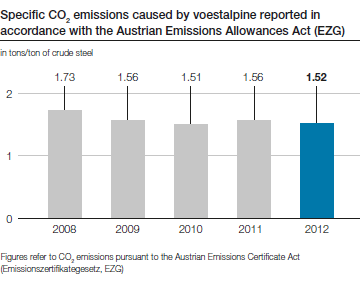

In the 2012 calendar year, the voestalpine Group emitted 1.5 tons of CO2 per ton of crude steel.

Measures to prevent and reduce CO2 emissions

Steel as an environmentally-friendly product

voestalpine develops those materials that enable vehicles, airplanes, and energy producers to provide mobility, heat, and energy efficiently with low emissions. In many of these applications, the emissions saved by using new steel components exceed by far the emissions caused by the production of these steel components.

The greatest savings potential can be found in the overhaul of fossil-fuel power plants, the expansion of wind energy, the reduction of passenger car weight, the increased use of combined heat and power generation, and of other renewable energy sources, such as geothermal, biomass, and hydroelectric power. Steel plays a key role in achieving ambitious climate targets. An efficient steel industry that can supply the necessary innovative steel products is an important contribution toward a successful climate policy.

Strict monitoring of emissions

A strict and technically mature monitoring system enables the voestalpine engineers to operate complex production facilities cost-effectively and sustainably, using environmentally sound technologies. This enables voestalpine to achieve production processes that are energy- and raw materials-efficient, resulting in a decrease in carbon emissions.

Active research efforts with regard to environmental technologies

voestalpine participates in EU-wide research projects by the entire steel industry whose objective is the development of low carbon steel production processes.

Development toward energy recovery and the highest possible energy efficiency

By exploring and realizing energy efficiency potential on an ongoing basis, voestalpine is achieving commensurate reductions in CO2. voestalpine supports the EU-initiative toward a paradigm shift in energy policies, in other words, switching to renewable energies, such as biomass or photovoltaics. This is the prerequisite to a reduction of the carbon emissions intensity in the EU in the long term.