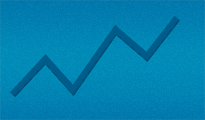

Environmental expenditures

The ongoing operating expenses of the voestalpine Group for environmental systems in the business year 2017/18 rose from EUR 231.5 million a year earlier to EUR 257.7 million; at about EUR 40 million, investments were as high as in the previous years.

Environmental expenditures

In millions of euros

1 In the business year 2015/16, in addition to the emission-intensive Austrian Group sites, a number of other, primarily international, production companies were included.

Environmental focus and measures

All of our efforts at bringing about sustainability are centered on the permanent optimization of process-related emissions and the continuous improvement of resource efficiency.

Hence the most important investment projects of the Steel Division with respect to environmental issues in the business year 2017/18 concerned a new water processing facility including the associated measurement and control technology and the requisite cooling water system; optimizing the use of steel mill gas; regenerative afterburning in connection with the drying of coal for the pulverized coal injection (PCI) facility in the blast furnace area; as well as various measures aimed at improving dust collection and dedusting (e.g. in connection with continuous casting and the coking plant). We also continued to work on the environmental project of the century, i.e. the “coking plant remediation.”

Environmental measures at the Metal Engineering Division focused principally on issues related to the blast furnace and sintering plant with the aim of reducing diffuse dust emissions by some 15 tons per year. Among other things, this includes the installation of a new misting system in the coke unloading area, the expansion of the local dedusting system in the coke and coal unloading area as well as the improvement of existing jetting systems at various conveyors. The High Performance Metals Division commissioned a new oil spray extraction system in Böhlerwerk, Austria, for example, which eliminates the oil and/or emulsion mists that arise in connection with profiling during the heat treatment and milling processes.

The Metal Forming Division implemented a number of environmental measures particularly at its facilities in China, among them systems serving to combat dusts containing phosphorous and ammonia and/or the associated pollution of surface water. This so-called Air Brewing System, which comprises a novel process for collecting the pollutants as well as diverting and vaporizing four tons daily of wastewater containing phosphorous followed by reprocessing, has a removal efficiency of 95%.

The energy self-sufficiency through renewables of the Company’s sites is consistently being expanded wherever there are adequate roof surfaces that satisfy the given structural requirements and offer economically viable options for using the generated energy. At the Kapfenberg site in Austria, for example, buildings were equipped with photovoltaics as part of a collaborative project with industrial partners. The expected output corresponds to the annual needs of up to 300 households. The feeding of the energy into the grid was agreed with a regional utility.

Ecological product considerations

The potential of steel as a material and/or of products made of steel and hence their life cycle assessment, i.e. the comprehensive ecological assessment of materials, is one of the linchpins of our environmental activities. In the past business year, additional projects were implemented or fleshed out, for example, with customers in the automotive or railway infrastructure industry. Besides preparing Environmental Product Declarations (EPD) and participating in the preparation of data sets, e.g. in cooperation with worldsteel (the World Steel Association), this also includes Group-wide activities regarding our water footprint.

Environmental management systems

Of the approx. 130 production-oriented Group companies worldwide listed in the environmental data management system, about 60% have an environmental management system (EMS) pursuant to ISO 14001, about 15% have also been validated under the EU’s Eco-Management and Audit Scheme (EMAS), and more than 20% utilize the energy management standard pursuant to ISO 50001. ISO 14001 is currently being implemented at the Group’s facility in Corpus Christi, Texas, USA, among other sites.

Besides operating/corporate issues, decisions on long-term energy and climate policies at the global, European, and national level as well as on the resulting planning options available to the Company have been and are at the heart of the Group’s environmental activities. Through a coordinated dialogue with stakeholders, in this connection voestalpine actively participates at several levels, both directly and via advocacy groups, in the political opinion-forming and decision-making process. The goal is to shape the political parameters that are key to the Company in ways that create a balance between long-term societal, social, and economic interests.

Energy and climate policy

The world climate agreement of the United Nations, which has taken effect by now, provides the framework for both the European and the national polity to act in respect of energy and climate policy and will replace the Kyoto Protocol from 2020 as the global climate protection agreement. In the meantime, the Paris Agreement has been ratified by 175 countries, including the European Union, and is being fleshed out step by step.

The EU and its individual member states have committed to abide by their “2030 Goals” in this connection and have established the “Energy Union” to serve as the framework for energy, climate, competition, and innovation policies. A key action package thereunder—“Clean Energy for all Europeans”—which is intended to address issues such as energy efficiency, expansion of renewables, energy market design, and overarching governance including the preparation of national energy and climate plans, is currently in a “trilogue” between the Commission, the Council, and the Parliament of the European Union. In the Company’s view, the global competitiveness of the European economy as a whole (and not just of individual sectors) must always be central to the decisions at that level.

The reform of the EU emissions trading system for the 2021 to 2030 trading period was finally adopted at the end of 2017. Despite an official carbon leakage protection level of 100% which, in actual fact, is insufficient due to systematic deductions, in our current estimation the voestalpine Group’s future needs for additional credits will correspond more or less to those in the current trading period, i.e. about one third of the Company’s total CO2 emissions. Aside from speculative aspects of the certificates market, the most recent price developments with respect to emissions trading certificates lead us to believe that, as a result of the decision, the voestalpine Group will be saddled with a rapidly growing financial burden in the future. In the business year 2017/18, the “CO2 price” shot up from EUR 4.86 to EUR 13.26 and thus by 172.8%, an increase that occurred largely after the date on which the resolution on the emissions trading reform was adopted.

At the national level, finally, voestalpine is part of a comprehensive stakeholder dialogue on the “Integrated Energy and Climate Strategy,” which was being decided upon politically at the time this annual report was prepared.

The H2FUTURE project

In order to support the development of energy management as it relates to the production of steel in the long term against this backdrop, at this time the currently largest and most advanced electrolyzer plant for the generation of “green”—i.e. CO2-free—hydrogen is being built at voestalpine’s Linz, Austria, site. Starting in 2019, the possibilities for using “green” hydrogen in the different process stages of steel production as well as the interaction with the grid’s electricity balancing market will be tested in the flagship project named “H2FUTURE – green hydrogen” that is being undertaken by the Fuel Cells and Hydrogen Joint Undertaking (FCH JU) as part of the EU’s “Horizon 2020 Program” and has a total investment volume of EUR 18 million. Besides voestalpine, the project also involves VERBUND as the provider of electricity from renewable sources; Siemens as the technology provider of the electrolysis module that was newly developed for the H2FUTURE project; the transmission system operator Austrian Power Grid (APG) as well as the scientific partners K1-MET and the Energy Research Centre of the Netherlands (ECN). After having been officially launched at the beginning of 2017, the construction work started in early 2018 once the construction permit was granted and has been largely completed by now such that the installation of the key electrical components is slated for the summer of 2018 and the commissioning for the end of 2018. The start-up of the extensive, two-year pilot program, which will run until about the middle of 2021, is planned for the spring of 2019.

A program entitled “Sustainable Steel” (SuSteel), which serves to develop a novel hydrogen plasma technology for the smelting reduction of iron ores and thus the direct production of steel from ore, is also being pursued at voestalpine. In this case, hydrogen plasma is to be used for reducing the oxides and the plasma energy for the smelting of the metallic iron. The fundamental feasibility of manufacturing steel directly from iron oxides by way of hydrogen plasma has already been tested and confirmed in bench-scale tests. To push the development for purposes of broader technological adoption, currently a pilot plant for the incremental adaptation of components and component groups is being built in Leoben/Donawitz, Austria.

Share page