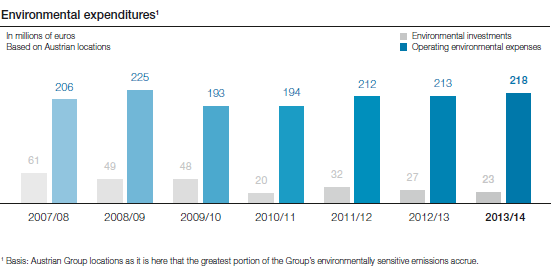

Environmental expenditures

In the business year 2013/14, the environmental investments of the voestalpine Group equaled around EUR 23 million (2012/2013: EUR 27 million); ongoing operating expenses for environmental systems totaled roughly EUR 218 million1 (2012/13: EUR 213 million). Thus, the voestalpine Group’s total environmental expenditures of EUR 241 million exceeded the previous year’s level by a negligible amount (2012/13: EUR 240 million).

The Group’s environmental projects in the last business year

During the last business year, as in prior years, voestalpine concentrated its main efforts in the environmental sector on air purification, water management, energy efficiency, noise abatement, waste disposal, and recycling management.

The focus of the air purification projects was to minimize dust emissions by installing new dust extractor and filtration systems—as well as entire dust extraction systems—primarily at its largest location in Linz, Austria, and at Villares Metals in Brazil. The Metal Engineering Division also substantially improved the occupational environment at one of its plants in China by optimizing the dust extraction systems there.

In regard to water management, the focus was placed on optimizing cooling systems during business year 2013/14. Thus, for example, the Special Steel Division switched some systems from open to closed cooling water systems at the Kapfenberg (Austria) location, while at the Krieglach (Austria) site of voestalpine Rotec GmbH (Metal Forming Division), the cooling system for the hydraulics station was switched to a security system that addresses leakage incidents.

Numerous measures for increasing energy efficiency were implemented within the Group over the course of the past several years. For example, today the production facilities at the Linz steel plant are largely reporting markedly lower specific energy consumption than just five years ago. Indeed, the plant attained an especially significant increase in energy efficiency with its blast furnaces. This can be attributed to generally optimized system configurations, the most robust operation of production systems possible, and comprehensive measures to increase energy efficiency, such as pump programs, state-of-the-art electric motors, optimized thermal processes, and reduction of standby energy consumption.

With regard to energy efficiency, the Special Steel Division successfully implemented the next phase of the fuel conversion from oil to liquid natural gas at the Uddeholm (Sweden) location. Additionally, a series of measures to improve output was established as a further contribution to energy and resource efficiency. In order to raise energy efficiency at other locations within the Division even further, additional measuring equipment was installed to monitor energy use.

Environmental management

As in previous years, over the past business year Group companies within the voestalpine Group were again awarded recognition for their implementation of measures in the environmental sector. Beside successfully obtaining initial ISO 14001 certification of the new voestalpine Steel Service Center in Romania, the efforts in the field of environmental management were also rewarded at the following locations: voestalpine Tubulars GmbH & Co. KG in Kindberg (Austria) received Austria’s EMAS award for its 2012 Environmental Declaration; furthermore, its energy efficiency efforts also garnered accolades with the klima:aktiv Award for Excellence in Climate Protection. The klima:aktiv award was likewise awarded to BÖHLER Edelstahl GmbH & Co. KG in Kapfenberg (Austria). Each of the following Group companies based in Zeltweg (Austria)—voestalpine VAE GmbH, voestalpine Weichensysteme GmbH, and voestalpine HYTRONICS GmbH—were honored with the 2014 EMAS Award for their long-term action plans in the area of “holistic life cycle optimization of product portfolios and production processes.” voestalpine Böhler Welding Group GmbH received an award as an “Eco-Profit Company” (ÖKO-Profit Betrieb) for its location in Hamm, Germany.

Environmental policy topics

The European Commission’s 7th Environment Action Programme (EAP)

The current 7th Environment Action Programme of the European Commission, which took effect at the end of 2013, forms the strategic framework for European environmental policy until 2020. It involves a series of 60 definitive measures of relevance to voestalpine.

The most significant challenge is represented by the ecological valuation of products across their entire life cycle through to their reuse or recycling. voestalpine already incorporates this balance both in the development of materials and then again in production. The ecological advantages of steel and thus, the environmentally sound performance of materials, contribute substantially to the company’s economic success. The Group ensures that this subject matter is consistently and continuously developed through the Group’s cross-divisional and cross-departmental Life Cycle Assessment (LCA) Team and its active collaboration in work groups and in advocacy and special interest groups on the LCA issue.

Climate and energy policy

In March 2014, the Council of the European Union instructed the Commission to develop proposals for a coherent climate and energy policy for the period from 2020 to 2030 by June 2014. It intends to vote on these proposals in October 2014.

The Council of the European Union determined that, in regard to the year 2030, it will give a binding target value for the EU’s CO2 emissions reductions. However, this “2030 climate goal” is not determined and adopted in isolation; rather, it is part of a political framework that will encompass the aspects of greenhouse gases, renewable energy, and energy efficiency.

In structuring the proposal for such a framework, the Commission must give equal weight to the treatment of the following aspects: affordable energy prices; industrial competitive ability; security of supply; achievement of goals for climate and environment; and, measures that would guarantee the competitive ability of energy-intensive European industries.

The Council of the European Union identified the lowering of the EU’s dependence on energy imports as an autonomous goal that—through broad diversification of energy sources—should enable the EU to achieve energy efficiency, network expansion, and the further development of subsidy mechanisms for renewable energies with regard to cost efficiency as well as the convergence of national systems after 2020.

From voestalpine’s perspective, these conclusions set the right course, in principle—but one that the Commission, in fact, must also delineate in adequate detail and clarity. Most of all, it requires—within the EU emissions trading system—free allocation by means of benchmarks that are technologically realistic and economically feasible, based on actual production, and without being restricted by additional “corrective factors.” In addition, a revision to the energy efficiency guideline is needed that would acknowledge industrial energy recovery as a worthwhile endeavor, rather than penalize such efforts.

Industrial Emissions Directive (IED); state-of-the-art technology

As previously illustrated in the prior year’s Annual Report, the revised version of the Industrial Emissions Directive (IED) 2010/75/EU became effective at the start of 2011, replacing the IPPC Guideline (Integrated Pollution Prevention and Control Directive). It is intended to guarantee the Europe-wide standardization of systems-oriented threshold values and measures for certain industrial activities.

In the interim, the national implementation process within Austria has advanced to the point that the requirements for maintaining state-of-the-art technology to prevent or ameliorate environmental pollution have been implemented, with respect to content, in the respective materials laws. These include, for example, the Waste Management Act, the Industrial Code, and the Water Rights Act.

At the integrated steel mill locations of the Steel Division and the Metal Engineering Division, pig iron and steel production areas underwent evaluation with regard to the need for adaptation or modification, by direct application of the IED and those documents that define the required environmental measures. In the findings, it was determined during the evaluation that as of the present date, configuration of the systems structure already complies with the “latest redefined” state of the art.

1 Basis: Austrian Group locations as it is here that the greatest portion of the Group’s environmentally sensitive emissions accrue.