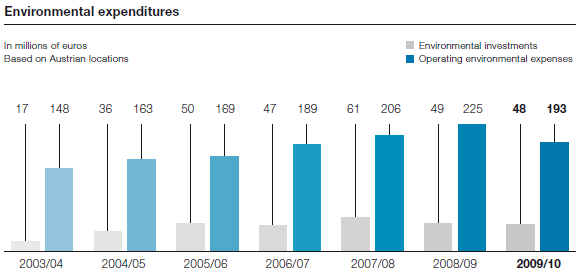

In the business year 2009/10, the environment-related investments of the voestalpine Group at just its Austrian sites came to about EUR 48 million, thus remaining at the high level of the previous year (EUR 49 million) despite the economic crisis. Due to declining production numbers, however, the current expenses for the operation and maintenance of environmental protection facilities, which had been at EUR 225 million for Austria in the previous business year, dropped to EUR 193 million in 2009/10. This results largely from somewhat lower operating expenses for environmental facilities and reduced disposal costs for production-related waste.

From today’s perspective, the financial burden for the purchase of CO2 certificates in the second trading period (2008–2012) will come to about EUR 50 million. The voestalpine Group already ensured the necessary number of certificates and has already purchased about half of them. The remainder will be purchased by the end of the second trading period.

Focal points of environmental measures

Despite the difficult economic circumstances, additional improvements in the areas of energy and raw materials efficiency, air and water emissions, and waste prevention were carried out at a number of Group locations in 2009/10. For example, the focus at the metallurgical plant site in Linz was two-fold:

continuing reduction of dust emissions in the blast furnace area and further optimization of the plant’s already very high degree of energy efficiency. Due to the start-up of operations of a new power plant block, utilization of gases generated in the production process can be improved even further for use in the self-generation of electricity that is currently at 90%; furthermore, by deploying state-of-the-art technologies, it is possible to achieve a further significant reduction of NOx emissions.

By implementing appropriate technical measures, emissions of site-specific harmful substances were substantially reduced at the Group’s Traisen and Kapfenberg locations in Austria, as well as at the Special Steel Division’s production companies in Sweden, Germany, and Brazil.

As is the case at the Group’s largest location in Linz, an improvement of energy efficiency is also a primary focus of environmental activities at the Donawitz metallurgical plant, where a new power plant unit was put into operation in October 2009. Additionally a new water supply and wastewater disposal concept has been implemented, which has brought considerable improvements with regard to environmental protection and energy recovery.

Awards for the voestalpine Group’s high standards

The Group’s environmental standards, which put it among the leaders in the field by international benchmarks, were again honored in the business year 2009/10 with a number of awards. To name just two examples, the lime works in Steyrling was awarded the Sustainability Prize 2010 by “Forum Rohstoffe” and the World Wildlife Fund (WWF) for changing to environmentally friendly mining practices, and VAE Eisenbahnsysteme GmbH received the European EMAS Award 2009 for green procurement in the category of “large corporations.” It should be noted that this Group company, whose 2009 National EMAS Award was its fourth, was the first Austrian company ever to receive this European award.

International thematic focal points

The setting of a future direction for a global CO2 regime that had been announced for December 2009 within the scope of the UN Climate Conference in Copenhagen has failed and has been postponed to the next conference at the end of 2010 in Cancún, Mexico. This means the state of uncertainty concerning the regulatory framework will continue so that reliable planning for investments in the European Union is impossible for many industrial companies.

The benchmark system for the European steel industry originally developed by voestalpine Group to achieve long-term reduction of CO2 emissions on a fair and standardized basis has now been recommended by the European steel association EUROFER and its member companies and is currently being negotiated with the European Commission. The basis for this benchmark system is a comprehensive collection of data regarding all plants and facilities of the European steel industry that will be affected by CO2 certificate trading from 2013 on.

Currently, the EU IPPC Guideline (Integrated Pollution Prevention and Control Directive), which was adopted in 1996, is being revised. A particular focus is a Europe-wide standardization of threshold values for industrial facilities, which will also be codified in the Reference Documents of the European Commission’s Best Available Techniques in the iron and steel industry. In the future, these threshold values may be adapted to local circumstances only with the European Commission’s approval and solely in justified exceptional cases.

On June 1, 2007, the EU chemicals regulation REACH became effective; its effects have already been described in detail in the previous annual reports. With regard to the implementation of these requirements within the voestalpine Group, we therefore refer to the quarterly reports on the business year 2009/10.