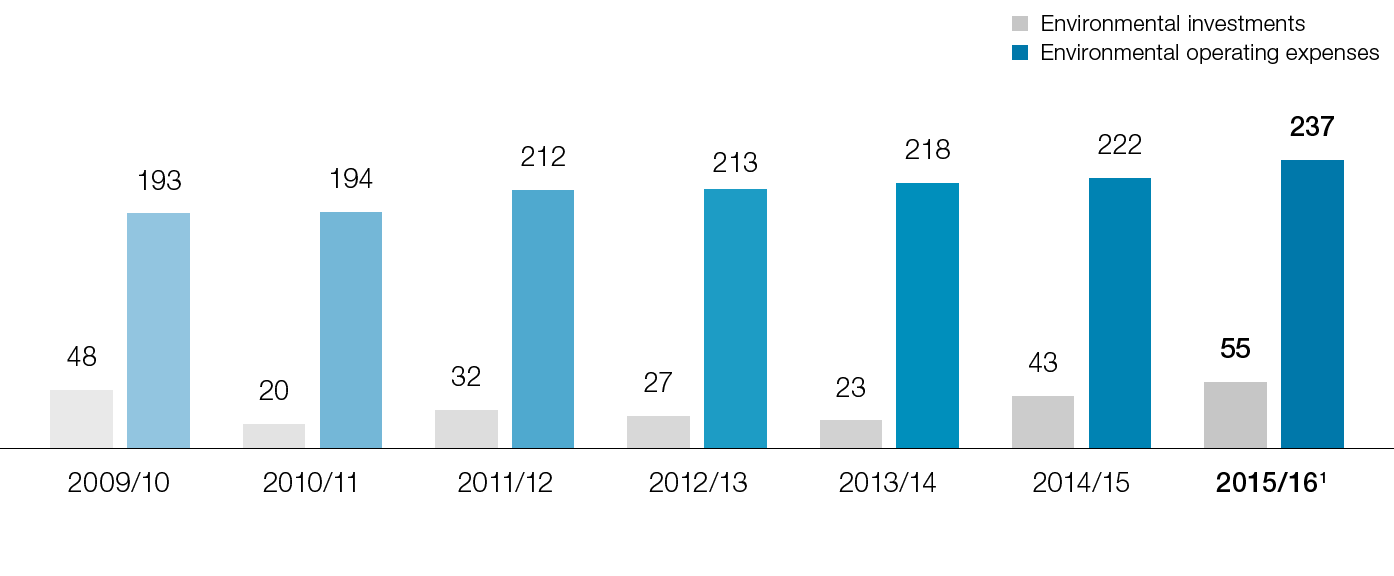

Environmental expenditures

In millions of euros

1 In the business year 2015/16, in addition to the emission-intensive Austrian Group sites, a number of other, primarily international, production companies was included. Based on the previously included Austrian sites, environmental investment rose by EUR 5 million from EUR 43 million in 2014/15 to EUR 47 million in 2015/16.

Environmental expenditures

In the business year 2015/16, environmental data management was significantly expanded. In addition to the previously reported emission-intensive Austrian Group sites, a number of other, primarily international, production companies and their facilities and systems were included for the first time. Environmental investment therefore increased compared with the previous year from EUR 43 million to EUR 55 million. There was also a slight increase in investment relative to previously included Austrian sites of EUR 5 million to EUR 47 million. Due to the expansion of the group of companies covered in the reporting, the ongoing costs of operation for environmental systems also rose from EUR 222 million to EUR 237 million, with the Austrian sites remaining at the previous year’s high level.

Environmental projects: highlights

Now that the Austrian Energy Efficiency Act, EEA (Bundes-Energieeffizienzgesetz, EEffG) came into effect at the beginning of 2016, utility companies must substantiate their energy savings by committing to appropriate efficiency measures at the consumer end. The voestalpine Group has complied with these requirements at all of its Austrian Group locations fully and on time. Simplified administrative procedures in connection with the implementation of the law will, however, be taken into consideration in the amendment that is currently under discussion.

The EU Industrial Emissions Directive, which is currently being implemented, affects a number of Group locations. For example, IPCC (Integrated Pollution Prevention and Control) facilities are subject to periodic environmental inspections. In the inspections carried out thus far of the facilities in question, no defects of a material nature were found. Furthermore, the directive regulates the prevailing state of the art of processes, facilities, and methods of operation, which is periodically defined in the BREFs (Best Reference Documents) and/or BAT (Best Available Techniques) conclusions. Today, voestalpine already meets the new standards that will not apply until the 2017 calendar year so that no material adaptations will be necessary.

A central focal point relating to sustainability, which will be significant in the long term, is a number of activities across the entire Group with regard to Life Cycle Assessment (LCA). This is understood as the comprehensive ecological product and process assessment of materials over their entire life cycle, from production through use to recycling. In addition to participation in the concrete definition of measurable and practice-oriented regulations, norms, and standards, both at the European and the international level, currently, a number of concrete LCA projects are being carried out with selected customers, for example, from the automotive and construction industries.

In the Steel Division, numerous additional systems were optimized in the past business year as part of a sophisticated environmental program to further lower emissions (for example, by using fewer reducing agents) and to further improve energy efficiency (including sharply focused measures in the areas of transport and logistics).

In order to consistently implement the Group’s high ecological standards outside of Europe as well, an environmental management system in accordance with ISO 14001 is currently being established at the new location in Corpus Christi, Texas, USA. The new direct reduction plant is considered an environmental benchmark as far as the facility’s technology is concerned. In addition to the use of the best available technologies to minimize air and water emissions, a briquetting plant processes filter dust and any ferrous production residue and recycles it back into the process (zero waste production with maximum raw materials efficiency).

Numerous environmental measures with similar objectives were also implemented in other divisions. For example, besides ongoing process optimization, the Special Steel Division completed a number of projects to improve energy efficiency (for instance, to curtail natural gas consumption) and to reduce air emissions, such as the new combustion facility at the site in Kapfenberg, Austria; a new dust removal system was installed at the electric-furnace steel plant in Wetzlar, Germany.

During its planning process for the new wire rolling mill in Donawitz, Austria, the Metal Engineering Division took comprehensive measures to lower energy consumption. For example, a new cooling system for the electrical buildings and transformer compartments was installed for the new rolling mill, with an even more energy-efficient combination of cooling water, a free-cooling system, and compression cooling. At the steel production plant in Donawitz, there will be substantial energy savings due to the newly developed cooling system for the walking beam furnace in the future; an integrated heat exchanger concept has been implemented that will also heat workshops and office space by way of a secondary circuit.

In the Metal Forming Division, three briquetting presses were installed at the site in the Austrian town of Kematen; they will make it possible to recycle the grinding dust, which is a valuable raw material due to its high iron content.

Current environmental topics

Global climate protection

In late 2015 in Paris, the international community agreed on a new UN global climate accord that will replace the previous Kyoto Protocol. A final assessment, however, to what degree this will actually be the case cannot be made as yet. This was an initial step toward the creation of a global climate protection framework that includes all emitters of greenhouse gases; whether or not, however, this will be an agreement that will be binding and comparable for all nations with fair competitive conditions for all market participants, as—not only—European industry hopes, is still uncertain because the most significant pillars of the agreement have not yet been concretely defined and the accord itself has not yet been ratified.

European level

In the European Union, the process to ratify the global climate accord (which must take place both in accordance with the laws of the European Union and at the national level of the member states) began formally in March 2016. The EU’s commitments related to climate change are identical with the well-known “2030 goals” (CO2 reduction by 40% compared with 1990).

The framework strategy for the concrete implementation of this ambitious program is the European Energy Union, which will connect and coordinate the main aspects of energy, climate, competition, and innovation policies. The EU Commission is planning to submit concrete recommendations for the legal implementation of this package by the spring of 2017.

The commission’s first draft for the planned EU emissions trading system for the trading period 2021 to 2030 has been available since the summer of 2015. From voestalpine’s perspective, however, the draft is problematic insofar as it stipulates yet another cutback of the overall number of certificates as well as another substantial reduction of the benchmark figures for the free allocation of certificates. Broadly based political negotiations regarding reform and the position of Austria in the EU Council are currently taking place. voestalpine’s view is unchanged that the key demands of 100% free allocation for the best performers based on real production benchmark figures, which are technically realistic, as well as adequate protection measures against carbon leakage be taken into consideration.

Share page