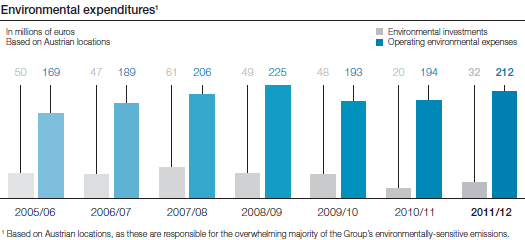

The environment-specific investments of the voestalpine Group in the business year 2011/12 equaled approximately EUR 32 million1 and were thus markedly above the last year’s figure of EUR 20 million. The current expenses for the operation and maintenance of environmental protection systems of EUR 212 million exceeded last year’s comparison value (EUR 194 million). Thus, in the business year 2011/12, the voestalpine Group spent around EUR 244 million (2010/11: EUR 214 million) for measures directly associated with environmental issues (including roughly EUR 10 million for CO2 certificates).

Focus of environmental efforts in business year 2011/12

In the past business year, a series of environmentally relevant activities were implemented. The focus was placed in the areas of energy and raw materials efficiency, air and water emissions as well as waste prevention and recycling.

The environmental measures at the Linz site (Steel Division) specifically concern: improvement of coking plant gas extraction for recycling in the integrated facility; reduction of hazardous waste in the sinter facility area by roughly one-third; new plans to optimize water management and further reduce dust emissions in the entire production process. Moreover, in the foundry, the Group achieved a marked reduction of waste while simultaneously increasing raw materials efficiency. The installation of a second separation stage at the existing chromite sand separation system will reduce the future consumption of new sand by 10%.

In Hagfors, at the Swedish production site of the Special Steel Division, the Group achieved a substantial reduction of certain emissions (nitrogen oxide, sulfur oxide, and dust) following the transition from oil and liquid gas to natural gas as a source of energy, which is more environmentally sound. Among a series of further optimization measures, one activity merits special note: the retrofitting of a blast furnace to the new regenerative burner technology, which comes with both ecological and economic advantages. At the division’s sites in Kapfenberg (Austria) and Villares (Brazil), the main focus was on comprehensive measures to reduce energy consumption in production.

In the Metal Engineering Division (until March 31, 2012 Railway Systems Division) at the Austrian site Zeltweg, the exhaust air from numerous welding and grinding processes is purified through the use of a new filter design, through which the filtered air can be recirculated back into the halls during the heating season. Through the up to 100,000 m3/h of recirculated air, Zeltweg can overall save an annual 1,100 MWh of thermal heat. Thus, the Zeltweg site is predominantly heated by the district heating network—fueled by biomass—and by waste-heat utilization (in other words: the site is essentially CO2-neutral).

In the steel and welding technology segments of the Metal Engineering Division, additional measures were implemented in the past business year to reduce emissions.

The companies of the present Metal Forming Division placed a permanent operational focus on the additional increase in energy efficiency and air quality control measures. In addition, the companies continuously make significant contributions to the sustainable optimization of resource utilization through product development. For example, at the British site in Birmingham, new profiles were engineered for modular systems whose advantages are primarily in the considerable weight reduction, compared to the previously applied standard, and in the roughly 10% savings on material coatings.

Focus of environmental policy

The draft prepared by the European Commission in December 2010 on the allocation mechanism for CO2 emission certificates that will apply for the period from 2013 to 2020 and that will be based on benchmark figures set by the EU has now become legally effective after the resolution was adopted by the EU Council of Ministers and the European Parliament on May 17, 2011. Consequently, the policy is being implemented nationally in Austria through a directive from the Austrian Ministry of Environment. However, the allocation mechanism as defined is being contested by the European steel association EUROFER and a number of businesses that are its members, including voestalpine AG. The relevant complaints that were brought before the European Court of Justice in July 2011 are in particular directed against the specific CO2 emissions requirements that cannot be achieved with the current state of the art.

Over the long term, probably the most significant—and also the most sensitive—topic in Europe with regard to the future of Europe’s most energy intensive industries is the “Roadmap 2050” that was outlined by the European Commission. The Roadmap envisions a largely carbon-free energy production and real economy in Europe by the year 2050. The exact delineation of the path to reduction for achieving this goal, and the evaluation of it at the industry level, are still pending. The European steel association EUROFER is joining in the related discussions, seeking foremost to prevent further intervention into the existing EU-certificates trading, which drives prices up, and to prevent the recent drastic intensification of the emissions reduction goals in the wake of the “Roadmap” discussions. Currently at the voestalpine Group, goals are being set and risks evaluated in detail. But possible long-term opportunities and potential are also being examined with regard to the strategic positioning of the Group (in relation to new, innovative materials and technologies, for example).

In regard to the topics already addressed in thorough detail in previous publications—Post-Kyoto/World Climate Conference 2011, Life Cycle Assessment, REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and Industrial Emissions Directive (IED) 2010/75/EU: Because the status has remained essentially unchanged, we refer to the last three letters to shareholders for the business year 2011/12.

1 Based on Austrian locations, as these are responsible for the overwhelming majority of the Group’s environmentally-sensitive emissions.