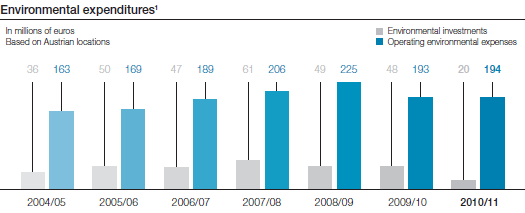

Development of environmental expenditures

The voestalpine Group’s direct environmental expenditures in the business year 2010/11 came to roughly EUR 20 million1. The steep reduction compared to the previous year’s figure (EUR 48 million) reflects the Group’s generally sharply diminished investments during and in the wake of the economic crisis. In addition, the latest eco-specific major investments were largely completed in the past business year at the two particularly environmentally sensitive metallurgical plants in Linz and Donawitz. The ongoing expenditures for operation and maintenance of environmentally relevant facilities1, however, remained stable at a very high level at EUR 194 million (compared to EUR 193 million in the previous year).

Thus, in the business year 2010/11, the voestalpine Group spent around EUR 214 million for measures directly associated with environmental issues.

Focus of environmental measures

In 2010/11, a number of other projects in the sectors of energy and raw materials efficiency, air and water emissions, as well as waste reduction and recycling were realized across the Group. In addition to the measures that were presented in detail in previous letters of shareholders with regard to the past business year, the following individual projects can serve to illustrate the Group’s efforts in this regard:

At the Linz site (Steel Division), new processing technologies in the blast furnace segment as substitutes for heavy oil (hand in hand with a significant reduction of sulfur emissions) as well as technologies to further sustainably reduce CO2 emissions by putting a natural gas injection facility into operation were developed and have already been successfully implemented in the production process. Other environmental projects in the Steel Division—all at the Linz location—pertained to the improvement of process water management and a reduction of NOx emissions as well as continued minimization of dust emissions (foundry).

In the Special Steel Division, at the site in Kapfenberg, Austria, new measures were taken that achieved a substantial reduction or, in some cases, prevention of discharge of heavy metal emissions in wastewater. The division launched a completely new water treatment system at its Brazilian location in Villares. This enables production wastewater to be optimally recycled. Furthermore, in the special forging segment in Wetzlar, Germany, measures were taken to reduce dust pollution by way of improved heat dissipation.

The Railway Systems Division has already distinguished itself in recent years by developing exemplary concepts for the optimization of the energy supply and the energy cycle. For example, at the turnout production site in Zeltweg, Austria, all thermal energy requirements are met by way of the district heating network that is fueled by biomass. By switching entirely to renewable energies, annual CO2 emissions are lowered by about 1,400 tons. Furthermore, by putting an hydroelectric power plant into operation at the same site, all electrical power requirements can be met in-house during the summer months.

Additionally, it should be underscored that comprehensive efforts are taking place at several of the division’s sites to expand occupational health and safety and energy efficiency as well as to lower noise and dust emissions.

It deserves special mention that in the past business year the Automotive Division launched a new technology for the generation of compressed air for compressor installations at one of its Austrian production sites, which minimizes cooling water emissions and, at the same time, enables savings of natural gas and electricity. Measures to reduce production-generated noise are another key focus of attention in the division.

A number of Austrian and international Group companies again received numerous awards in the business year 2010/11 for their outstanding standards in the areas of the environment and occupational safety. This time, the focus of the honored projects and measures was in the sectors of energy (generation, efficiency, and energy cycle) and occupational safety. A particularly important award was the “European Good Practice Award in Safety and Health at Work,” which VAE Eisenbahnsysteme GmbH, Zeltweg, received in April 2011 for the second time for its outstanding performance with regard to occupational safety and health.

Environmental agenda

The benchmark system to succeed the Kyoto Protocol recommended by the European steel association EUROFER and its member companies was, for the most part, rejected by the European Commission. This decision was made although the comprehensive collection of data ordered by the European Commission regarding all plants and facilities of the European steel industry that will be affected by CO2 certificate trading from 2013 on, upon which the recommendation was based, was verified and confirmed as plausible by an independent authority.

As, in the meantime, the separate draft of the allocation mechanism, which was prepared by the Commission in December 2010 and stipulated its own benchmark figures, has passed both the EU Council of Ministers and the European Parliament, it is on the verge of taking legal effect. The European steel companies within EUROFER, however, have decided to contest the benchmark system recommended by the EU because some of the threshold values cannot be achieved with today’s technical possibilities. From the current perspective, the result of this proceeding is largely up in the air.

Currently, the future course for a new economic structure of the EU that was recommended by the Commission in the “Roadmap 2050” is being discussed by top European decision-makers. The recommendations include CO2-free electricity generation, massive innovations in the transportation sector, acceleration of construction of low-energy buildings, and changes in the manufacturing industry to reduce CO2 and increase energy efficiency. Apart from the fact that the objective of these ambitions is basically a welcome one, from the perspective of the voestalpine Group, the Roadmap seems, for the most part, to be lacking a holistic approach across all of the impacted value chains. With regard to the steel industry, almost no attention is paid to the fact that in recent years a significant part of European manufacturers have already reached the limits of what is doable in terms of environmental technology (and in terms of finances).

It is in particular the focus on production-generated CO2 emissions as the main management and control instrument for the industrial transformation that the Roadmap is aiming for that disregards the overall importance of the steel industry in the value chain on the one hand, and the concrete importance of steel as a material on the other hand. From today’s vantage point, neither the product and process innovations required in the transition phase nor future technologies, which are as CO2-neutral as possible, in the sectors of energy and mobility can be implemented without the significant use of steel (e.g., in the transportation and energy infrastructure sectors, for efficient energy systems, or in the sectors of transportation and logistics). This includes not only the supply of materials of the required quality and in the needed quantity, but also their supply at prices that enable downstream processing companies to create sufficiently high added value to make it even possible to finance the desired transformation.

The steel industry should therefore be an integral component of the entire process chain, not just with regard to its CO2 output but also with respect to its potential to achieve the very objective that the EU Commission is aiming for by using its comprehensive problem-solving competence, and be included appropriately in long-term deliberations.

1 Basis: Austrian locations, as it is here that the greatest portion of the Group’s environmentally sensitive emissions accrue.