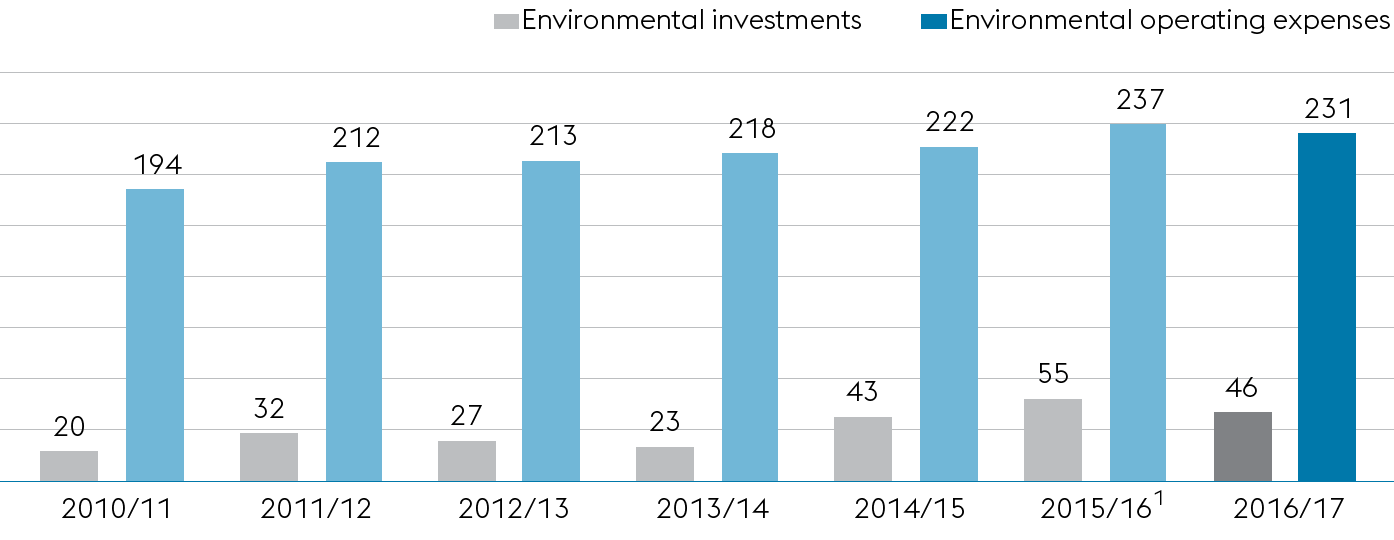

Environmental expenditures

Since the business year 2015/16, in addition to the previously mentioned emission-intensive Austrian Group sites, several other, primarily international, production companies and their respective data were included for the first time as well. Overall, the ongoing operating costs for environmental systems of EUR 231 million have dropped slightly below the level of the previous year (EUR 237 million). At the same time, the voestalpine Group’s environmental investments also decreased from EUR 55 million in the previous year to EUR 46 million.

Environmental expenditures

In millions of euros

1 In the business year 2015/16, in addition to the emission-intensive Austrian Group sites, a number of other, primarily international, production companies were included.

Environmental focus and measures

Besides continuous energy efficiency improvements, the Group’s focus in terms of environmentally relevant projects is on a further reduction or prevention of production based emissions in the air and water as well as on waste disposal. In the Steel Division (Linz, Austria), numerous additional system optimizations were performed in the past business year as part of a very ambitious environmental program to further lower emissions and to further improve energy efficiency, in particular in the areas of infrastructure and logistics. Amongst others, the installation of a new conveyor technology as part of the major repair of blast furnace 6 ensures a sustained reduction of burden dust. The now—as of April 1, 2017—fully operational direct reduction plant in Corpus Christi, Texas, USA is a true environmental benchmark from a technological perspective with its heat recovery system, recycling of process gases and enclosed conveyors and ore deposits and, with the use of natural gas rather than coke, marks an important first step toward a CO2-reduced steel production within the Group.

With about EUR 16 million, the largest single environmental project was successfully completed at the High Performance Metals Division (formerly Special Steel Division) Kapfenberg site in Austria in the previous business year. In the special steel plant’s new “pickling shop 4.0”, emission-relevant processes (pickling, coating, salt bath) are now performed in a fully enclosed system (tunnel system). Offgas streams are purified by means of fume scrubbers, an optimized process reduces waste water volumes by 80%, and resource efficiency is increased while hazardous waste (pickling slurry) is reduced by about 25%. The electric-furnace steel plant at the Division’s Hagfors site in Sweden was equipped with a new, significantly more efficient filter system. Besides emission reductions of 50%, it also helped reduce noise pollution noticeably.

A number of similar and lastingly effective investments were also made in the Metal Engineering Division, such as the expansion of the sprayer systems at the sinter plant (blast furnace) in Leoben/Donawitz, Austria, to reduce diffuse dust emissions by about 25% on all conveyor routes. In addition, air pollutants and energy consumption were further reduced at that location thanks to a new walking beam furnace for the rail production, and the commissioning of the new wire rod mill also ensures a significant reduction of energy consumption, air emissions (primarily nitrogen oxide), and waste water volumes.

Environmental management systems

A large number of voestalpine Group companies have a broad range of environmental management systems (ISO 14001 or EMAS) and a certified energy management system (according to ISO 50001) in place. With the turnout production sites in Germany, more companies followed suit in implementing such systems and obtained certification in the past business year. DIN EN ISO 14001 certifications were also completed or will be obtained in the current business year by the automotive components segment of the Metal Forming Division.

Ecological product considerations

Besides operative environmental measures, the ecological potential of steel as a material and as a product is the focus of optimization measures. Besides innovations in lightweight construction for the automotive sector, the railway infrastructure, and renewable energy applications (such as solar and photovoltaic solutions in the Metal Forming Division), this also includes the “Life Cycle Assessment”, i. e., the overall ecological assessment of materials over their life cycle. In addition to its active involvement with interest groups on a national, European and global level—primarily to establish objective criteria such as measurability and comparability of assessment standards—voestalpine is also pursuing concrete projects in this regard with important customer industries (such as the automotive industry).

Research and development of CO2-reducing technologies

The technological research and development of alternative steel production processes is being advanced in particular by a cooperation between voestalpine and VERBUND AG, Vienna, Austria, that focuses primarily on flexibility concepts in energy production and energy demand (“demand-side management”) as well as on a research cooperation for future-oriented hydrogen developments. At the beginning of 2017, the Linz site in Austria launched “H2FUTURE” as part of an EU-funded project, which involves a pilot facility for the production of “green” hydrogen from water by means of electrolysis using renewable energy sources. The objective of this project that is scheduled to run until 2021 is to identify potentials and options for the use of hydrogen in the various process steps of steel production. The project is valued at about EUR 18 million and also involves SIEMENS, K1-MET, APG (Austrian Power Grid) and ECN (Energy Research Centre of the Netherlands). In addition, further development projects, such as a test facility to study reduction processes with hydrogen plasma, are being advanced at the Leoben/Donawitz site in Austria.

Long-term energy and climate-political pursuits

At the global level, the UN global climate accord came into force on November 4, 2016, which is to replace the “Kyoto Protocol” as the global climate protection framework in 2020. The ecological process established at the World Climate Conference in Paris in November 2015 (in particular with regard to the evaluation and monitoring of climate protection measures) is now being substantiated and implemented. The “Paris Agreement” offers a historical chance to make climate protection contributions of major emitters binding and broadly comparable.

The EU as well as the individual member countries incorporated the “2030 Goals” that were decided upon already in 2014 in the global climate accord; since their resolution—regardless of the global context—these have formed the basis for the European Energy Union which establishes the European framework strategy for energy, climate, competition and innovation policies. Accordingly, by 2030, CO2 emissions in the EU must be decreased by at least 40% compared to 1990. However, even more stringent reductions by 43% compared to 2005 apply for the sectors subject to the emissions trading system, such as the steel industry.

At the end of November 2016, the EU Commission presented comprehensive legislative proposals to the European Energy Union titled “Clean Energy for all Europeans” that cover the areas of energy efficiency, renewable energy, organization of the electricity market, power supply security and managing the Energy Union. In addition, the Commission proposes new ecodesign options as well as a strategy for networked and automated mobility.

The separately handled reform of the emission trade system for the trade period from 2021 to 2030 has been in negotiation with the Commission, the Council and Parliament of the European Union since March 2017. The objective of the discussions is to reach an agreement on key points with in part greatly diverging positions on the part of the three institutions. From voestalpine’s viewpoint, the focus remains on sufficient availability of free certificates, their allocation mechanism (e. g., based on reasonable benchmark values) as well as the maximum inclusion of energetically used blast furnace gases in the assessment. A sound evaluation of the emission trade reform and its implications on voestalpine can only be performed after the trialogue or a legal definition of the result, i. e., probably not before the end of 2017. From the present point of view, it is to be expected that the voestalpine Group’s need to purchase additional certificates in the period from 2021 until 2030 will remain approximately at the high level of the current trading period.

On the national level, voestalpine is engaged in an in-depth dialog with political decision makers about the integrated and national energy and climate plan which Austria will subsequently be introducing to the European Energy Union in the near future (at the latest by the end of 2018). The goal of the negotiations is to establish the framework conditions relevant to the Group (particularly in terms of economy and competition) in such a way that the voestalpine Group does not suffer any competitive disadvantages in the global market.

Share page